Last Updated on July 11, 2022

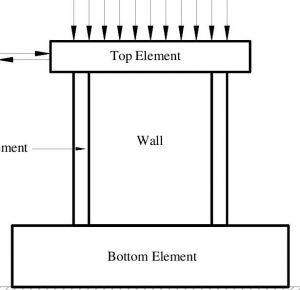

Shear wall is a structural element that is used to withstand lateral forces or forces that are parallel to the plane of the wall. Shear walls withstand loads by means of their cantilever behavior. Shear walls, in other terms, are vertical members of horizontal force-resisting systems.

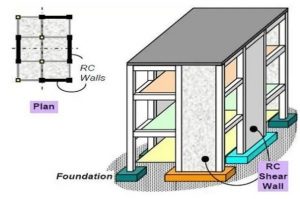

A shear wall, a rigid vertical diaphragm capable of transferring lateral stresses from external roofs, floors and walls to the ground foundation in a direction parallel to their planes in building construction. Reinforced concrete walls and vertical trusses are two examples of shear walls.

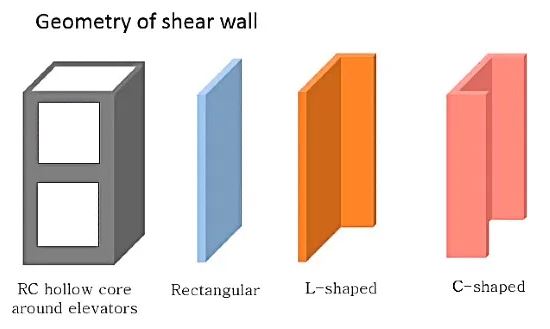

Types of Shear Wall Used in Construction

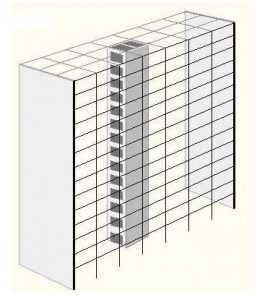

1. Steel Plate Shear Wall

Steel plate shear wall is a modern lateral load-resisting system that may efficiently brace a structure against both wind and seismic loads. The system is made of one-story-high, one-bay-wide vertical steel infill plates that are joined to the surrounding beams and columns. To construct a strong cantilever wall, the plates are placed in one or more bays for the whole height of a structure. Steel plate shear wall is well-suited for new construction and provide a very easy method for existing steel or concrete structures to be more resistant against earthquake.

Steel plate shear wall has several considerable advantages, including high ductility, architectural flexibility potential, high energy dissipation capability, a simple evaluation and adjustment technique for strength and stiffness and a reasonably easy fabrication and construction procedure. A number of tests and analytical studies of its ductility, energy dissipation capacity and stability behavior were carried out due to its great seismic performance and potential for engineering applications.

2. Reinforced Concrete Shear Wall

Reinforced concrete shear walls are an effective way to stiffen a building’s structural system under lateral stresses. A shear wall’s primary role is to improve the stiffness and strength of the building for lateral resistance. Shear walls have extremely high in-plane stiffness and strength, allowing them to resist significant horizontal loads such as wind or seismic forces in addition to gravity forces. RC shear walls must be carefully built to give sufficient strength as well as ductility to avoid brittle shear failures. Several shear walls around the world have been damaged by earthquakes due to poor design and detailing or construction problems.

Reinforced concrete shear walls have long been recognized as acceptable structural solutions in RC structures, offering both lateral resistance and drift control. These older shear walls, on the other hand, were generally constructed for combined effects of gravity loads and wind loading. In day-to-day mid-height building structures, seismic loading and design were not taken into account. In fact, seismic provisions were not implemented until the 1970s; as a result, the majority of structures designed and built before to that time have deficiencies in design and details. These shear wall structures are prone to seismic hazard due to weaknesses in their design.

Buildings with cast-in-situ reinforced concrete shear walls are common in many earthquake-prone countries including Canada, Romania, Chile, Turkey, Colombia and Russia. This style of construction has been used in urban areas for medium to high-rise structures since the 1960s. Shear wall structures are typically regular in plan and elevation. However, lower levels in some buildings are used for commercial purposes, and the structures have greater plan sizes on those floors. In certain situations, higher floor levels have setbacks. Shear wall structures are often utilized for residential purposes and may accommodate between 100 and 500 people.

3. Concrete Hollow Block Shear Wall

Concrete block shear walls are built using hollow concrete blocks and steel reinforcement bars. Reinforcement is commonly utilized to improve the seismic resistance of concrete block masonry. Reinforcement bars are placed in both vertical and horizontal directions via concrete block gaps. Following the installation of the bars in the concrete block masonry, fresh concrete grout is poured into the hollow area and allowed to set. This sort of wall can withstand both gravity and lateral stresses. As a result, they may function as both a shear wall and a load bearing wall.

In the case of a large earthquake, special reinforced masonry wall systems constructed in accordance with existing regulations and practice may fail to operate as expected. This is because seismic design provisions focus largely on strength and reinforcement details, without taking into account the actual behavior of a wall system under severe seismic events. A performance-based design method may be used to guarantee that the structural system functions reliably in order to maintain a constant level of safety and performance. Masonry shear walls are built of hollow concrete blocks with filled mortar and rebar on-site to counteract these lateral forces. They are most commonly utilized in smaller buildings.

4. Midply Wood Shear Walls

One ply of sheathing material is installed in the middle of the wall between a sequence of pairs of studs and plates that are 90° turned relative to typical shear walls. The new wall style is known as “midply” because of the placement of the sheathing panel. Nails connecting frame members to sheathing in midply walls function in double shear, as opposed to connections in conventional shear walls, which work in single shear. This significantly improves the shear performance of midply walls. The load-carrying capability of midply walls is more than three times that of equivalent conventional shear walls.

Innovative designs have been developed in order to expand the usage of timber construction for nonresidential applications. Some of these applications are industrial structures, low-rise commercial buildings, and so on. midply walls have demonstrated the most potential for non-residential structures in terms of their capacity to withstand significant earthquake and wind forces. An increase in the size of midply shear walls was recommended for larger non-residential construction applications. Studs, sheathing, nails and other midply shear wall components were increased.

The midply shear wall was designed to be utilized as a structural system in the event of a major earthquake. For non-residential structures, this form of construction has developed as a viable alternative to concrete and steel. The midply shear wall employs a unique arrangement of sheathing and framing elements, as well as a unique nailing process. The failure mode of the midply joints is different from that of ordinary shear walls.

5. Plywood Shear Walls

Plywood shear walls are a form of conventional shear wall that is also known as timber shear walls. It is made of plywood sheets and studs. Shear force is transferred by plywood sheets and tensile and compressive stresses are resisted by studs. Nowadays, plywood shear walls are being modified to get benefit from new technological advances. Sure boards, steel sheets and other materials are being used in place of plywood. Plywood shear walls are made of plywood to transmit shear forces, chords to withstand tension/compression caused by overturning moments and base connections to transport shear to foundations.

Types of Shear Walls with respect to Size

1. Short Shear Wall

A shear wall is considered as a short shear wall if its height/depth is less than 1. Short RC shear walls with low reinforcement ratios are prone to brittle shear failure, limiting deformation capacity and seismic performance. To counteract this shear failure mechanism, new codes focus more on capacity design. To meet the modern seismic design code standards, it is necessary to enhance the RC shear wall strength and deformability while preserving the wall energy dissipation capacity.

For the reinforcement of RC walls, several strengthening techniques have been developed and are in use currently. Reinforced concrete jacketing, steel-plate bonding and fiber-reinforced polymer (FRP) reinforcement are some examples for it. The FRP strengthening approach is the most common because of its ease of application, light weight and excellent corrosion resistance.

2. Squat Shear Wall

A shear wall is considered as a squat shear wall if its height/depth ratio is in between 1 and 3. A squat shear wall is a structural member used to restrict axial and lateral stresses. In contrast to slender shear walls, squat shear walls often failed by shear before the drifting from lateral stresses. These failures are undesirable because they always occur after elastic deformation and may cause the entire building structure to fail. While resisting axial load, the stress distribution of a shear wall is the same as that of a column, and when resisting lateral loads, it is the same as that of a beam. However, the existence of an opening on the shear wall has produced a disturbance in the stress distribution. As a result, the size and location of the shear wall must be evaluated and analyzed throughout the design process.

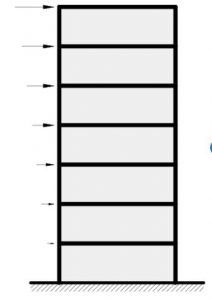

3. Cantilever Shear Walls

A shear wall is considered as a cantilever shear wall if its height/depth ratio is greater than 3. When compared to short shear walls, the cantilever shear wall exhibits flexural behavior. The bending behavior is same to that of a cantilever beam. The cantilever shear wall exhibits convex behavior throughout the building’s height. The structure, which has stiff frames and short shear walls, has a concave form in the upper part and a convex shape in the lower part.

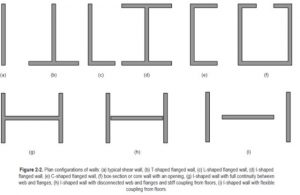

What is Flanged Shear Wall?

Flanged shear walls are widely utilized to counteract lateral stresses caused by earthquakes in mid and high-rise structures. As a result, the seismic performance of many structures is strongly linked to the behavior of the reinforced concrete walls. They must be properly constructed to offer not just enough strength, but also adequate ductility to avoid brittle failure under severe lateral stresses, especially during an earthquake.

Recent earthquake recordings show that ground movements in the immediate area of a rupturing fault can contain a significant energy or directivity pulse. A directivity pulse develops when the fault propagates at approximately the same rate as the shear wave velocity. This pulse is visible in the rupture’s forward direction and can inflict significant damage during an earthquake, especially to structures with natural periods similar to those of the pulse.

The lateral and gravity load-resisting system is made of reinforced concrete shear walls and slabs. Shear walls are the primary vertical structural components that withstand both gravity and lateral stresses. A mong the types of shear walls, flanged shear walls generally have different strength, ductility and stiffness capabilities in the two opposite directions when loading stress is parallel to the web of shear wall. According to experiments, structures with flanged walls will have less structural damage during moderate earthquakes than structures without flanged walls.

How does a shear wall work?

A structural engineering degree may be required to fully understand the physics of shear walls, but visualizing a wooden square with four edges—basically two columns and two beams—will help you understand how shear walls work. Compressive loads can be supported by this frame since any force applied to the upper beam is transmitted via the columns to the square’s base.

The square will twist and fail on itself if you apply too much force to its sides (lateral force), unless you place braces with supports. These bracing are placed on shear walls, which are built to prevent self-collapse.

Therefore, they guarantee that your house won’t be destroyed by wind or an event which causes lateral forces such as earthquakes.

Several windows, bays, doors, recesses, and open floor designs can be found in many modern homes.

These elements and the structure’s design do not provide the stability required to allow the structure to resist the applied lateral loads. As a result, internal shear walls are often included in home designs and construction plans to provide stability required for the structures such as houses and apartments. By doing this, you can have your structures that have enough endurance for the external forces and ready to be utilized by yourselves.

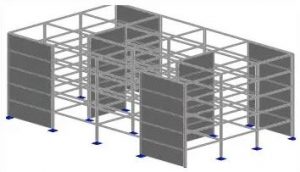

Location of a Shear Wall in a Building

There are primarily two arrangements; one is positioned at the building’s edges and can either have a plane shape or a flanged shape. The other is positioned inside the structure as channel sections or core walls.

These walls are typically positioned in the center of tall buildings, usually as a core wall system to support lifts and other vertical translation systems.

In thıs article, shear wall in construction is explained. Hope you enjoyed it!