Last Updated on July 13, 2022

Tensile strength of steel is defined as the resistance of steel to breaking under tensile stress. It’s used to define the transition from elastic deformation to plastic deformation in steel. It’s usually expressed in force units per cross-sectional area. A piece of steel will break apart after it has been taken past its tensile stress limit. Tensile strength of steel indicates how much tensile stress it can resist before having a ductile or brittle failure.

What is Ductile Failure?

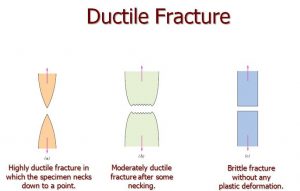

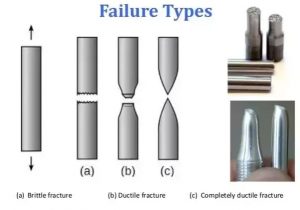

A ductile failure occurs when a malleable object is subjected to extensive plastic deformation or necking. This normally happens before the material fails completely. The failure of highly ductile materials is referred to as ductile rupture. Instead of cracking, materials pull apart in those situations. Significant amount of energy are absorbed and propagated slowly in ductile failure before the fracture occurs. Ductile fracture is also another term for ductile failure.

Under a static load, the majority of ductile metals show necking and plastic deformation. These plastic deformations appear before the materials’ final rupture. The shape of the fracture surfaces allows us to observe a significant proportion of the ductile failures. The ductile fracturing of metals under tensile loads can be seen as a cup and cone form. The cup and cone fracture phases can be described as; neck, small cavity forming, formation of cracks and cup and cone fracture.

What is Brittle Failure?

Brittle fracture is the abrupt, very fast cracking of elements under stress, with little or no signs of ductility or plastic deterioration prior to the fracture. When an element experiences a brittle fracture, there is no thinning or necking, unlike most other tensile failures, where the structure plastically stretches under overload conditions and gets thinner to the point of rupture.

Low temperatures are a common cause of brittle fracture. Brittle failure is possible if the steel temperature is at or below its brittle-to-ductile transition temperature. When you combine this with a critical-sized flaw and high tension on the flaw, you’re likely to get a brittle fracture.

Brittle fractures, like ductile fractures, have a distinct fracturing surface. A brittle failure’s fracture surface is normally fairly smooth. The crack spreads in the material with a process known as cleavage.

Tensile Strength of Steel

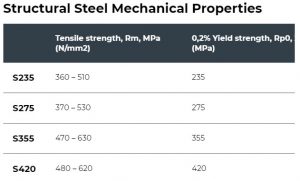

Steel is one of the most popular building materials. It is commonly used in everything from residential construction to skyscrapers and is praised for its flexibility, incredibly high tensile strength and value. Steel comes in a variety of types that are used in construction. Each has distinct properties and as a result, specific applications in construction. Tensile strength of steel is very important for beams, slabs and columns used in construction.

The amount of tensile (stretching) stress that a material can resist before cracking or failing is referred to as its tensile strength. The ultimate tensile strength of a material is determined by dividing the area of the material measured (the cross section) by the stress applied to the material, which is commonly expressed in MPa or Newtons per square milimeter of material. Tensile strength is a valuable indicator of a material’s ability to perform in an application, and it is commonly used to describe the properties of metals and alloys.

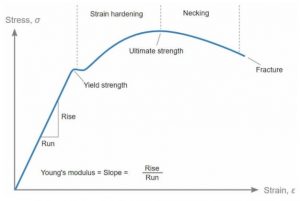

1.Yield Strength

When being under stress, a material undergoes recoverable deformation. A material’s yield strength indicates the stress beyond which its deformation becomes plastic. Any deformation caused by stresses greater than the yield strength is permanent. Because of the linearity of elastic deformation, yield strength is also known as the greatest stress achievable without deviating from the stress-strain proportionality. Large deformations can be found beyond this point with little or no increase in applied load. Yield strength is calculated in Newtons per square milimeters (N/mm2) or Mega pascals.

If the applied stress is less than the yield strength of steel, steel metal will regain its original shape when the stress is released. Yield strength is generaly denoted with Fy.

Yield strength formula:

σy = Pyp /A0

where Pyp = load at the yield point,

A0 = original cross sectional area

When a material is under stress less than its yield stress, it will only undergo elastic strain(elastic deformation), with no permanent deformation.

2.Ultimate Tensile Strength

Ultimate tensile strength, also known as tensile strength or ultimate strength, is the highest force that a material can resist before rupturing or breaking when stretched or pulled. Tensile strength is the opposite of compressive strength, and the two may have very different values.

Ultimate tensile strength formula:

σmax = Pmax /A0

where A0 = original cross sectional area,

Pmax = maximum load

This value is usually much higher than the yield stress (as much as 50 to 60 percent more than the yield for some types of metals). Necking occurs as a ductile material exceeds its maximum strength and the cross-sectional area gets smaller locally. There is no stress on the stress-strain curve that is greater than the ultimate strength. Even though deformations will continue to escalate, until the ultimate strength is reached, the stress usually decreases. Since it is an intensive property, its value is independent of the size of the test specimen. However, it is affected by other factors such as specimen preparation, the existence or absence of surface defects, and the temperature of the test area and material.

Difference Between Tensile Strength and Yield Strength

The maximum stress that a material can withstand before irreversibly deformed and losing its ability to return to its original dimensions is known as the yield strength (It is where after plastic deformation begins). The maximum tensile stress at which a material would fail and break is known as tensile strength or ultimate tensile strength.

Tensile strength of steel or ultimate tensile strength of steel is the maximum stress that steel can withstand before failing. Yield strength of steel is the magnitude of stress that makes steel to lose its elastic behaviour.

How to Measure Tensile Strength of Steel?

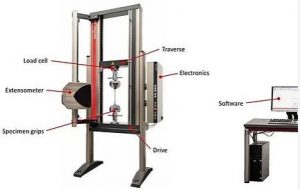

Tensile testing, also known as tension testing, is one of the most basic and widely used methods of mechanical testing. Tensile testing involves applying tensile force to a material and measuring the specimen’s resistance to the stress. Tensile measurements determine how strong a material is and how much it can elongate by doing so. Tensile tests are commonly performed on electromechanical or uniform testing instruments, are easy to carry out, and are completely standardized.

Tensile testing will reveal a lot about a material. We may obtain a complete profile of the material’s tensile properties by testing it as it is being pulled. As this data is plotted on a graph, it produces a stress/strain curve, which indicates how the material responded to the applied forces. The point of failure is of primary interest, but other important properties to consider include strain, yield strength and modulus of elasticity.

What is Elongation of Steel?

The percentage of stretch, or elongation, from the steel’s original length to the point of failure shows how ductile the metal is. The ability of steel to be stretched out without becoming more brittle or weaker is known as ductility. The product is more formable when it is more ductile. Elongation is a useful measurement to consider when deciding if the product you’re selecting is the best fit for the project.

In other words, the term “elongation” refers to a mechanical property of metal, specifically the amount that a material can be stretched or compressed before it ruptures. It is shown as a percentage of the original length and lies between tensile strength and yield strength.

What is Elongation Formula?

Elongation can be calculated with the following simple formula:

Elongation = ɛ = (ΔL/L) x 100

Where:

L: Initial Length

ΔL: Final Length

Let’s look at an example:

Find percentage elongation of a steel rod, when it is subjected to an axial pulling force of 50 KN whose diameter is 30 mm and it is 3 meters long. Take E= 200 X 10^9 Newton per meter square.

A = π*30^2/4 = 706.5 mm2

ΔL = (P*L)/(A*E)

ΔL = 50*1000*3*1000/(706.5*200*10^3) = 1.0616 mm

Elongation = (ΔL/L) x 100 = (1.0616/3000)*100 = 0.0354%

Tensile strength of steel has been explained in this article. Hope you enjoyed it!

Pingback: Types of Forces and Stresses in Civil Eng. | techyildiz